| Date interviewed | 9 & 10 October 2018 |

| Date newsletter posted | 2 November 2018 |

| Farmer | Kurt Stock |

| Farm | Segoma Sugar |

| Mill | Pongola (diversions to USM and Felixton) |

| Area under cane | 245 hectares |

| Tonnes to mill | 22 000 tonnes to the mill this year |

| Other income streams | Veggies, cattle, Irricheck, Dragon Fruit, Maize seed, game farm |

| Cutting cycle | 13.1 months (would like to be 12 if mill could cope) |

| Av Yield | 94 tonnes/hectare previous season (101 currently this season) Still recovering from poor condition of purchased farms. |

| Av RV | 12.4% |

| Best Yield | 142 tonnes / hectare (Sunhennop rotation crop, plant cane) |

| Best RV | 16.5% LONG dry off period. Variety based result |

| Varieties | N25, N53, N36, N46 – on the way out |

| Distance from the mill | Av 4.2kms from mill (6 different farms) |

Kurt is the Chairman of the Pongola Canegrowers’ Association (besides many other things) and in this capacity has been on my radar, whilst skilfully avoiding an interview, for 2 years. He graciously explains that his media-shyness began back in 2015 when he was Runner-Up in the Young Farmer of the Year (KZN) competition. Kurt isn’t the first one to tell me that media focus like that brings attention from many other unwanted sources. But, as soon as we decided that SugarBytes could hardly be classified as Media or compared to anything as grand as YFY we made progress. SugarBytes is just a little bi-monthly inspirational tool for SA sugar cane farmers, with the only readers being fellow industry compatriots. An interview is a harmless way to share learnings and encourage other farmers in their endeavours to improve their operations.

That settled, I found myself visiting Segoma Sugar on a perfect day in October.

Kurt is of German descent; when his grandfather first came to SA in 1949 he managed the cotton gin in Magudu. He then purchased a small cotton farm in Swaziland in 1957. Running his Swazi farms and working in SA, he then purchased a cattle and cotton farm in SA in 1963 which then grew into citrus and sugar cane. Kurt’s Dad, Rob, continued in this area and Kurt was born here.

Kurt and his wonderful, mischievous, charming Dad, Rob

Kurt and his wonderful, mischievous, charming Dad, Rob

Kurt is a Weston Agricultural College Old Boy who then went on to Lowveld Agricultural College where he graduated in 2001. Thereafter, he spent a year in Australia, completing his prac year. Fully theoried-up and full of energy, he returned to the family farm ready to implement all he’d learnt. And then the land claim was gazetted. That was 2003 and a time of turmoil for Kurt and his family – their cattle had also contracted contagious abortion disease and couldn’t seem to shake it.

In true Kurt-style, he quickly pulled himself into gear and devised a plan forward. His plan was two-pronged: they sold most of the farm to the state and turned the rest into a game farm, inviting a couple of other investors in. This freed Kurt up to move onward and upward. With his new bride on his arm (yes, that beautiful lady in the Pongola Sugar offices, Antoinette Stock, is married to Kurt) the family moved west, to Pongola, and started again. That was 2008.

When they bought the current homestead farm, the cane fields were yielding only 50 tonnes/hectare but the fleas were in top form; it had been a poorly managed hunting dog breeding facility. The dogs had gone but no one had told the fleas that.

Since then, they’ve come a long way and Kurt is finally feeling like he had a solid base on which to improve. He certainly does not claim to be a top farmer but he does aspire to become one. They have six farms (plus the game farm), with 245 hectares under sugar cane.

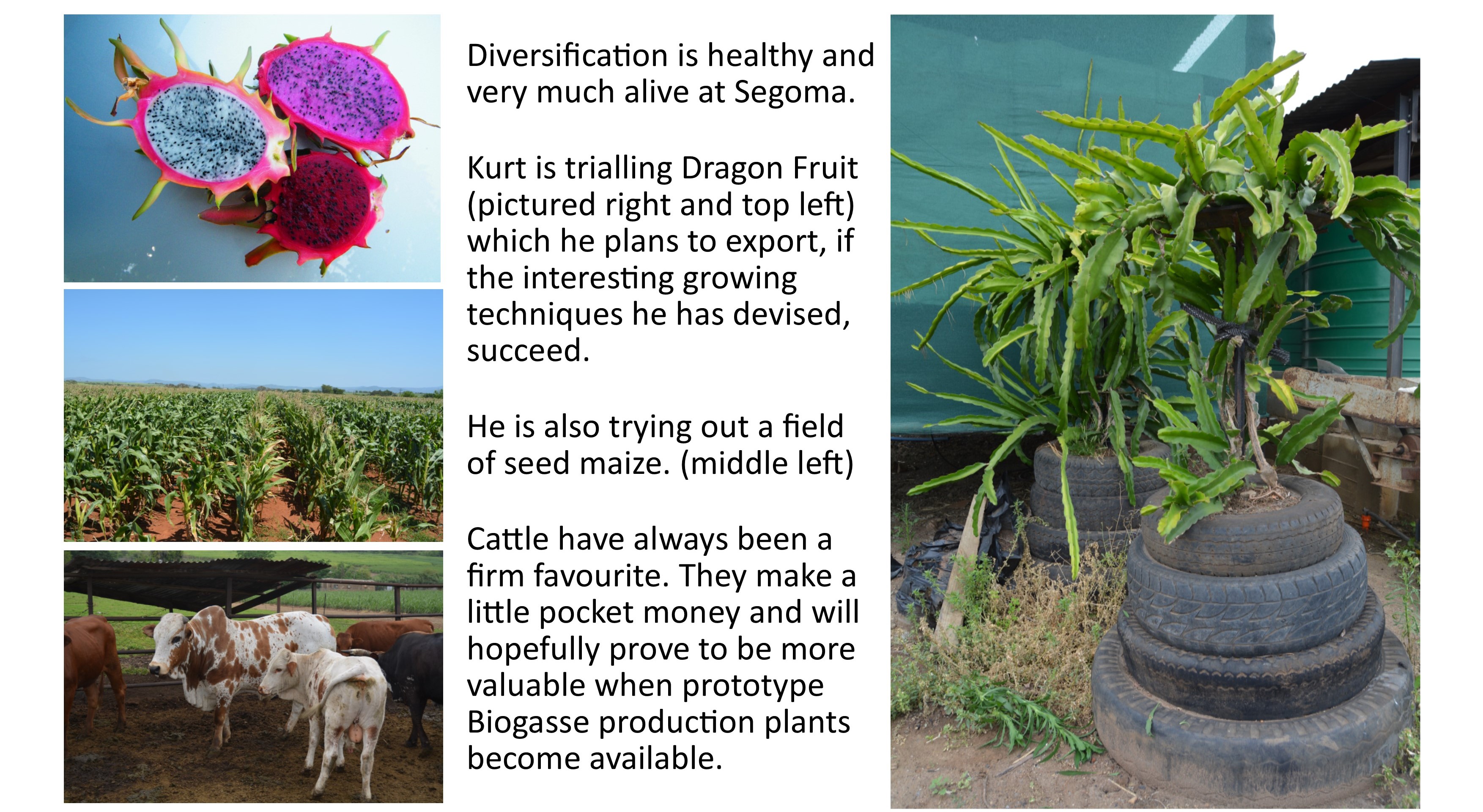

DIVERSIFICATION

Besides more than his fair share of involvement in the administration of organised agriculture and local community initiatives, Kurt also diversifies his farming portfolio.

Besides those mentioned above, veggies also have a prominent spot in this operation.

And still, he finds time to diversify out of agriculture as well: he is involved in a network marketing initiative and he is the Northern Natal, Southern Mozambique and Southern Swaziland agent for Irricheck. He is completely committed to being a successful farmer in South Africa but feels it would be short-sighted to neglect a Plan B entirely, should land redistribution without compensation become a reality. It is for this reason (and a sincere passion for the initiatives) that he has added independent businesses to his plate.

SOILS

It is clear that this farmer is a thinker, planner and pioneer and he has applied these qualities to the sustainability of his lands. “How can we expect soils that have been farmed intensively for 50 to 60 years to continue producing the results we need?” asks Kurt, “it is absolutely imperative that we put back as much, if not more, than we take out with each crop.” To this end, Kurt employs a few strategies that he collectively calls ‘biological farming’:

- Crop rotation

- Maximising trash contribution

- Green manuring

- Organic Content

Crop Rotation: Whenever a cane field is replanted, it is first fallowed and, in that time, veggies or other rotation crops are planted. Sometimes this can kill two birds with one stone: one of the rotation crops Kurt uses is Black Oats. They draw the salts up out of the soil, into the leaves. The cattle then move into the field and feed on these leaves, thereby removing the salts from the field and enjoying a few nutritious meals. The remaining stems and roots are incorporated back into the soil as rich organic matter. If veggies are planted, they provide necessary additional income … so, that’s actually three birds I think.

Trash: Although I whole-heartedly believe in and support green cane harvesting, I can see that it would be difficult at best and impossible at worst to practice this in some Pongola fields. The cane just gets so big, long, lodged, twisted and heavy that it would take herculean strength to manhandle in a ‘fully-leafed’ condition. I think Kurt has struck a decent compromise in running a cool fire through the field before harvesting. Thereafter, all remaining trash is considered valuable and is carefully swept aside when fertilisers are applied and then replaced between each row to conserve moisture and decompose into organic matter. The cool fire not only preserves trash but also limits heat damage (drying out and micro-life destruction) to the soil.

This 12-month old field is almost completely lodged – just a few lone sticks remain vertical.

This 12-month old field is almost completely lodged – just a few lone sticks remain vertical.

Green manuring: Although related to the two points above, green manuring is a focal practice. By actively incorporating any organic matter back into the soil, life, nutrition and moisture content is all enhanced.

Organic content: Being so close to the mill, Kurt can take advantage of their need to dump mila and he is a happy recipient whenever it’s available. He also buys in kraal manure.

Kurt assigns most of learnings in biological farming to Ernst Höll and John Fair.

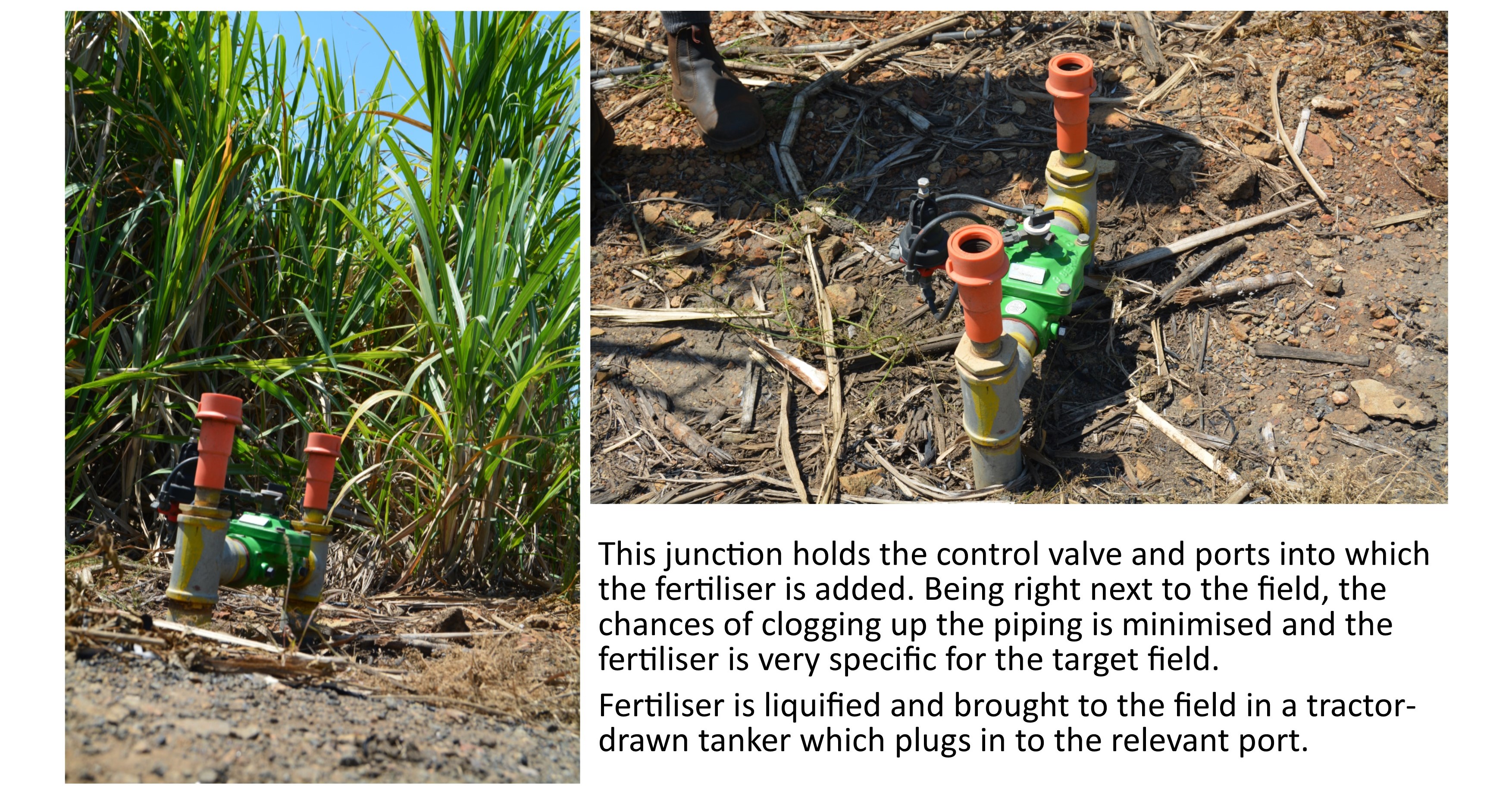

FERTILISERS

Although Kurt values the natural approach, he doesn’t think it’s enough to replace soil nutrients used in farming intensively and he therefore supplements with commercial fertilizers. Key in his management of this sector is VARIETY; Kurt switches it up constantly. He changes application methods, fertiliser types and timing to include all options and thereby covers all the bases.

Application methods: Kurt rotates three main application methods: ripping the fertiliser in (as shown in the pic below), broadcasting and banding. Each year a different method is used.

Fertiliser types: Kurt alternates using LAN and urea-based nitrogen. If it’s urea-based that’s going to be used, he’ll generally employ the ripping method of application so that volatilisation is minimised. He explains that you have to be very careful if you chose to broadcast urea BUT he does say that Kynoch’s new KynoPlus (using Agrotain technology) is one of the best ever. This product can be broadcast with very little risk of volatilisation.

Generally, Kurt uses a 7:1:6, a 5:1:5 or a 1:0:1.

Organic fertilisers play a huge role on this farm, especially during planting. As mentioned, kraal manure is incorporated into the soil during the fallow period. This has to have been matured for about 2 years prior to application in order to lower the excessively high nitrogen levels. Mila is also used.

In keeping with his dynamic approach to farming, Kurt is open to trying new things. Two products that he says has earned themselves permanent places in his planting regime are ProAct and Myconate. ProAct is a product that works on the Harpin protein and claims to assist germination, yield and plant health by triggering the plants defences (it thinks it’s under attack). Myconate stimulates Mycorrhizae fungi to boost nutrient and water uptake and build long term healthier soils. Both of these products are sprayed onto the cane sets in the furrows when planting. The assumption is always that these organic supplements are too expensive, so I asked Kurt about that: “It costs about R130 -R140 per hectare the way I do it, which is to spray in the furrow when planting and then maybe one further application on the leaves a few weeks later (with ProAct). This is less than the product packaging recommends but it works for me in terms of cost and results.”

Timing: Split applications are standard practice during winter with the second application taking place in spring. Fields harvested during spring and summer are given their fertiliser in one dose.

This inconsistency in fertiliser management is very deliberate; a way of ‘spreading your eggs into many baskets”. Everyone you speak to will have a valid justification for the way they do things and they generally stick to a single method year in and year out. What if everyone is right, and all methods / products have unique advantages? Shouldn’t we then employ them all? This is Kurt’s reasoning behind incorporating many variants into his programme.

Some other advice from Kurt in fertilising: try to apply the phosphorous right next to the sets in planting. This mineral doesn’t travel well therefore needs to be ‘spoonfed’ to the plant. He uses about 1 tonne per hectare of MAP and then top dresses with nitrogen and potassium when the cane is about waist-height.

Usually Kurt uses straight elements when planting and blends on ratoon cane.

As soil nutrition is a critical area at Segoma, they spend a lot of effort in ensuring that they understand exactly what the soil needs:

- Multiple soil analyses. Most of the soil samples go to the SoilTech for analysis but Kurt likes to validate the feedback he gets from any laboratory by comparing it with another facility’s results. Generally, SoilTech is spot on.

- Listen to the rotation crop. Whatever crop is grown during the fallow period may present symptoms that can be attributed to soil imbalances that can be corrected before the cane is planted.

HERBICIDES

Weeds build resistance and are Nature’s way of rebelling, in fact they’re part of God’s curse on the world. Suffice to say, we’re not likely to eradicate them entirely anytime soon. Instead, Kurt chooses to tolerate a certain amount and fight clever with the rest. Farmers Agricare is his trusted ally in this battle. As most challenges in the cane fields are grasses, most herbicides target grasses. But sugar cane is a grass too and, for this reason, Kurt believes we need to be very cautious with what and when we spray. He chooses to spray pre-emergent herbicides directly after a cut so that the germinating cane is not damaged. He uses new and different products all the time – he calls it a ‘programme of constant rotation’. This way, he not only addresses the issue of chemical resistance but can also focus on the season’s star ie: whichever weed he sees in abundance in the area. This year, it’s looking like Johnson grass and his programme will therefore incorporate something specialising in killing this specific grass. (pictured below)

Weather forecasts also play a part in deciding what to use eg: wet weather generally boosts the Buffalo grass.

When it comes to plant cane, his approach is far gentler. Here he uses softer, pre- and post-emergent chemicals that are registered for use on plant cane, simultaneously, when there has been a show of germination. If there are just too many weeds he’ll use Gramoxone just to knock everything back. Key is to avoid letting the situation get out of control.

There are no more hoes on Segoma Sugar. The high cost of labour and the poor results of hoeing have led to this decision. Instead, any weeds surviving the initial blanket herbiciding are dealt with by knapsack sprayers. Below we can see where a Gramoxone / Diuron mix has been spot sprayed onto some kweek. If this kweek is found in a field exceeding 1m in height, Roundup is used.

IRRIGATION

If we had to single out an area in which Kurt should be considered an expert, it has to be irrigation.

Optimal plant health is the goal of almost every farmer. The plant is nourished and sustained by the soil, moisture being a key component of its makeup. Understanding this, Kurt set out to establish how he could provide the best moisture for optimal soil and plant health. He came across Irricheck, who not only supply and install the probes to read soil moisture, they also provide transmitters, flow meters, rain-gauges, weather stations and software that integrates actual weather, forecasted weather, soil characteristics, crop phenology and irrigation methods to provide a live, web-based, 7-day forecasted irrigation recommendation, ie: how much to irrigate, when.

Drip irrigation was recently installed into this field and it’s doing very well.

Drip irrigation was recently installed into this field and it’s doing very well.

By the time Irricheck needed an agent in the area, Kurt was already a fan and happily took up the role. His active involvement in irrigation, across many operations has taught him some valuable lessons:

- Almost everyone over-irrigates, to the detriment of the crop. Over-irrigated soil conditions lead to an anaerobic environment and the beneficial soil microbes will die. It’s amazing how little water a plant can actually thrive Essential spores in the soil require moisture to activate and AIR to survive. Too much water will also leach the fertilisers out of the soil.

- All methods have their advantages and disadvantages – yup, you guessed it: Kurt has spread his eggs across many baskets and has a little of each form of irrigation on his farms. His favourite seems to be drip though …

- Probes are great, but you need to know what to do with the readings they give you and effective software to convert it into meaningful and useful information you can act on reliably. To make full use of this technology, many other factors must go into formulating the irrigation schedule for your farm.

- The whole climate needs to be taken into account when making irrigation decisions, especially the wind. Much like human bodies, plants require more hydration in dry, windy conditions, even though we feel cooler.

- Irrigation schedules must be adjusted per season. This would seem logical as climates are vastly different during different periods of the year. Kurt says I’d be amazed at how few people implement this logic. One of his Irricheck customers phoned to say that the probes weren’t working because he hadn’t been told to irrigate for 2 months during winter this year. After a quick excavation of the area, it was established that the subsoils were actually still sufficiently moist and the probes (together with the software) knew that. Water and energy have been saved and these fields are thriving!

Now, 80% of Kurt’s farming is based on water management. One of his best decisions was to only buy farms that lay below the Pongola irrigation system and one of the farm’s irrigation is entirely gravity fed, saving a whack on energy costs.

Kurt’s Hortex weather station measures wind, temperature, rain, relative humidity and sun radiation. All this information is factored into the irrigation schedule supplied by the Irricheck programme.

Kurt’s Hortex weather station measures wind, temperature, rain, relative humidity and sun radiation. All this information is factored into the irrigation schedule supplied by the Irricheck programme.

Types of irrigation

Flood is great but only feasible if the gradient and soils are suitable. Kurt uses this method where he can but also has a centre pivot, drag lines and semi-permanent installations. In terms of ease, centre pivot has to be the favourite – it’s simple and easily maintained, very little can and does go wrong. The scheduling is also basic.

But, if Kurt wants to really apply himself and do it properly, he believes drip irrigation has the most advantages: you can fertigate, no matter what stage of growth the field is at. No need to move sprinklers. The water is delivered to the customers (roots) door, minimising evaporation and waste. You are also not locked in to any kind of schedule (like in sprinklers and pivots) and can turn the system on and off as necessary. You can customise the size of the dripper holes and thereby accommodate soil variations across a field.

There are, of course, inhibitors to drip: not every farmer is a drip farmer as it requires lots of attention and care, in filtration and flushing particularly. Without adequate maintenance it can bankrupt you. Changing to a drip system can be expensive, depending on whether you chose subsurface or not. Kurt currently uses surface drippers because he needed to make a quick change. Subsurface requires new equipment and a different loading method and management of infield traffic. Pulling out the driplines every year can be a chore but there is always extra labour at some stage during the 8-10 week lead up to harvest during which the lines can be pulled without compromising other tasks on the farm. Kurt has also developed a tool that rolls the lines up neatly:

HARVESTING

Kurt visibly winces when I ask about his experience in this department. He explains that he was a part of a group that tried mechanical harvesting in 1998/9. The exercise almost bankrupted the lot of them. As we have just published an article on loading, it might be interesting to look at the lessons learnt in this near-disaster.

Kurt says that the failure probably had more to do with the management practices taught to them (or not taught to them) when the machine was commissioned than with the harvesting method itself.

- They were told to ridge the soil. The ratoons were thereby perfectly placed for maximum damage.

- Irrigation was not adjusted when they changed to mechanical harvesting:

- The ridges caused water to dam up.

- They did not factor in the moisture retention effects of the trash. (Green cane harvesting with all the trash being returned to the soil)

The bottom line was that ratoon and soil damage caused by heavy equipment on wet soils was so extensive that yield just plummeted (from an average of 115 tonnes/hectare to around 80) and the project shut down after about 9 years.

Now, he loads for the mill in-field with tri-wheelers and only uses zones in wet weather. After his mechanical harvesting nightmare, I was intrigued to hear why he still ran a relatively uncontrolled (in that the loaders cross rows and inter-rows) traffic system in-field. He explains that he has chosen to focus on areas that HE feels makes the biggest difference, that being soil health. After so many years of withdrawing nutrition from the soil he thinks that restoring that content is of greater urgency than addressing once-a-year soil compaction. Changing a harvesting method requires substantial capital investment in terms of suitable equipment and that is not possible right now. Perhaps it will be an area of focus in the future. That doesn’t mean to say that Kurt doesn’t address compaction substantially between plantings: he rips and cross rips after the final harvest. He then discs 2 or 3 times depending on what rotation crop will be planted in the fallow period. When that crop is finished he then ploughs to incorporate the organic matter into the soil.

Careful trash management

Careful trash management

Harvesting is now done as a part of a group and treated as a separate enterprise; KMB Harvesting Contractors, who also handle loading and transport to the mill.

If you’ve ever wondered about the benefits of employing contractors over running these functions in-house, here is some sound advice from someone who has done it both ways:

Hiring in contractors:

- Removes labour issues from your plate.

- Removes safety and security issues from your plate.

- Removes all those hidden costs from your bill. Items like smocks and transport are often excluded when assessing the cost of harvesting in-house yet they all add up.

For Kurt BEING the contractor, it has allowed him greater flexibility; if an obstacle crops up on one farm, there’s always another that needs harvesting. Economies of scale and maximum use of all equipment also has a financial spin off for the contractors and therefore those using the contractors. He can also harvest a greater area in less time, freeing up labour to attend to maintenance and other farm duties.

When the cane stands vertically it’s very impressive, as seen in this fully-grown field of N25.

When the cane stands vertically it’s very impressive, as seen in this fully-grown field of N25.

ADMINISTRATION

Clearly (from Kurt’s many administrative roles) he does not have a problem with the soil-free side of farming. In fact, it drives him – he likes to be informed and contribute to the industries he makes a living from. “It is essential that more youngsters realise that stuff doesn’t just happen, someone has to do it. By getting involved and doing your share for organised agriculture, the whole society grows positively.”

When it comes to his own personal administration on the farm, Kurt explains that accurate records and proper use of the information is crucial to his decision-making and success. Although he feels that he has lots of room to improve in this department, now that the drought is behind them, the new farms are settling in and the new offices are complete, he’ll become a lot more organised. There is a detailed board up in the shed whereon all the farm activities are recorded, even the method of application when it comes to fertilisers.

From a software perspective, he uses Plan-A-Head. An advantage is that this software is sold in ‘pieces’ ie: you can buy the parts you need, one at a time. He has the wages, vehicles and cane production modules currently. Plan-A-Head is also close to finalising the appointment of a trainer in the Pongola area who will be able to provide support for all customers.

PESTS AND DISEASES

Pongola always enjoyed a relatively pest-free status until the drought. This meant that, when the crops became stressed in that dry spell, and pests became more of an issue, no one was adequately prepared for them. Scouting was not a common practice and, when pests and diseases were found, the correct plan of action was not clear. Although the region is recovering from the drought hang-over, a few challenges still need to be dealt with:

- Pineapple disease is addressed by applying a powder mix of either Benate or Benamyl when planting.

- The climate has favoured smut lately – dry, timing of the rain, plant stress levels. There are no chemicals for this disease, the plants must be removed manually, taking care not to spread the spores. N41 & N25 seem to be particularly susceptible.

An example of smut (not on Kurt’s farm)

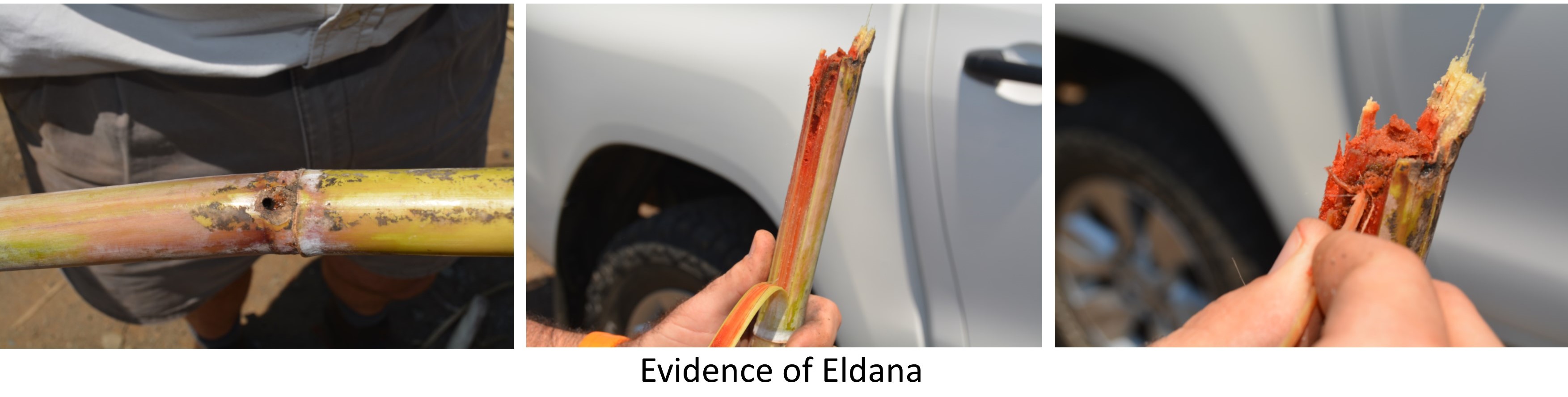

- Eldana – this little critter is proving to be a real challenge lately. Compounded by the fact that Pongola mill capacities have been exceeded and stand-over cane volumes increase relatively. Kurt might have to spray this year, for the first time ever.

- N49, in particular, was hit hard this year and Kurt has to nail down when to spray and what to spray to protect his crop. This year, he missed the effective window and it has probably cost him tonnage but, when compared to cost of spraying, it might be 6 of one, half a dozen of the other…

- Thrips are dealt with by applying Bandit when planting. Sometimes it appears on older ratoon cane but generally, by the time it’s been spotted, the damage is done and there’s nothing you can do about it. The 12-month growing cycle certainly doesn’t allow much time for anything!

LABOUR

Kurt works hard and expects the same from his staff. Hard workers are well remunerated, laziness is not tolerated. Everyone works on a task-based system and payment aligns with this. Any incentives are realised at the end of the year, depending on how well the farm has performed.

Communication is thorough with regular farm meetings being held to explain what is being done and why it is being done that way. Kurt makes sure that all tasks are handed out with an explanation eg: he doesn’t just hand out sprayers, he explains WHY they’re spraying, he doesn’t just tell them to take rocks out of the field, he explains the damage they cause to the mill and the farm’s equipment. These explanations are integral to the commitment and enthusiasm of the workforce.

VARIETIES

Kurt advises that varieties should be selected based on soils and then trialled before planting extensively. He currently has 4 varieties in one field and will use the most successful variety as seedcane across further fields. Making sure you are clear of your goals is critical; do you want quality or weight? When Kurt farmed in Mgudu, quality was vital because of the distance from the mill but, here in Pongola, 4 kms away from the mill, maximising yield is primary.

EDUCATION

Perhaps it is because my own children are venturing towards independence or maybe it’s because I sometimes question my own tertiary education but I like to hear about what education farmers think builds a great farmer … Kurt would steer clear of an agricultural speciality; he did that and believes that, if your passion is farming, you have that sector covered. He’d suggest that you add business skills to your repertoire rather, as this is essential to running any operation and can be used if farming doesn’t work out (unfortunately, SA farmers need to think about plan B more than most). Agricultural school is character building but is not a fall-back if farming fails.

PEARLS OF WISDOM

And continuing in that vein, what would Kurt say to a young farmer looking for general advice?

- You cannot concentrate on only one thing on your farm, you have to have eyes on all the balls in the air. Become the Master Jack of All Trades, quickly.

- Accept that farming today is not what it was for our fathers; it’s no longer a simple career. The extensive choices can complicate our lives and lead to frustration. They had 3 oils to choose from when servicing the tractor, we have 53! Keep focused, clear and informed, thereby equipping yourself to simplify choices.

- Stay positive. The oppressive weight of all the legislative requirements place a load on the operation. You need to address this head on, with a strategy that will allow you to stay compliant and positive.

- Stay current. This is difficult for smaller operations but always do your best to at least stay informed of current technologies and test them when and where you can.

- Involve yourself in organised agriculture. Most farmers avoid this, expecting that someone else will handle it for them. Be that someone for yourself. Staying involved and informed not only empowers you to filter harmful rumours, it also keeps you on the cutting edge of industry news and opportunities. No one can farm as an island and having half the information is sometimes more harmful than having none at all.

- If you want to farm SA soil, then do it, 100%. Scratching in the soil whilst constantly looking over your shoulder for the land grabbers is a recipe for failure. Do the job properly or go. Farming won’t tolerate half-heartedness, it’s not an easy job anymore. Kurt’s not saying that you shouldn’t have a plan B – that’s wise, but commit fully to plan A until it comes time to step to plan B.

And there ends my time in Kurt’s world. It certainly is a full one but one that is also highly organised. I even get the impression that he’s not yet at capacity. Thank you for making time to share your experience and learnings with us all, we look forward to watching you reach your full potential in the years ahead.