| Date interviewed | 22 March 2018 |

| Date newsletter posted | 20 April 2018 |

| Farmer | Bruce Zunckel |

| Farm | Havelock Farm |

| Mill | Darnall (ave 12,5kms away) |

| Area under cane | 340 hectares |

| Other crops | Macs (52 hectares), Litchis (6 hectares – about 70 years old) |

| Cutting cycle | 14 month average |

| Av Yield | 83.6 t/h last year. Ave 73t/h over last 20 years |

| Av RV | 12.02% last year. Like to sit around 12,5% |

| Best Yield | 180t/h – a field of N36 that was 18 months plant cane |

| Best RV | About 15% |

| Varieties | N12, N47, N41, N36, N55, N58 and N52. N27 & N39 being taken out. |

| Distance from coast | About 3kms as the crow flies |

I had booked a ‘double feature’ today and left the Goss residence at midday to spend the afternoon with the Zunckels, who are literally next door. The rain was still bucketing down and I was pretty soaked from trying to get pictures on Thamsanqa … I was caught between being so grateful that these farmers had the rain they desperately needed and selfishly wanting a small window in which to get a few nice pics …

Mike Zunckel, Bruce’s Dad met me as I arrived and showed me in to the beautifully decorated, 154 year old homestead, with its thick walls and grand, high ceilings. Mrs Zunckel (Cheryl) welcomed us warmly with freshly baked deliciousness and hot coffee. I’m in love already! Bruce, who is obviously the chief farmer nowadays, arrived and we got straight to business …

HISTORY

Mike grew up on a large piece of land in Bergville. The land had been in the family for 140 years but his dad was a prospector and hunter so, after Mike finished school in Hermansburg, he began developing it from a small commercial farm into a thriving enterprise including maize, soya, beef, seed potatoes and wheat. Unfortunately, the 90’s brought trouble in the form of land invasions and the Zunckel property, being on the border of a location, caught most of the heat. Cheryl hails from a sugar farming family in the Groutville area (and still has lots of family in Kearsney). They would spend time at the beach during school holidays and it was during one of these retreats that they heard about a local farm, recently on the market, and took a look. By 1996 they had moved on to Havelock Farm, selling the Bergville property shortly thereafter.

Bruce is a College old boy and says he studied at Cedara after school … I had to giggle when, at this point, Mike smiled mischievously at Bruce and asked, “Did you?” Clearly Bruce also fitted in a lot of fun whilst there. After that, he spent a few years travelling and working around the world but when his brother was tragically killed in a car accident at 20 years old (the same crash that took Darryl Goss’s life) Bruce came home and started to settle down.

That was 18 years ago and quite a bit has changed since then: there are now an additional 200 hectares of sugar cane, but 3 less hectares of litchis, and the ‘favourite child’ has been established – it is clear that Bruce is very passionate about farming macs. There are currently 52 hectares, with plans to expand to 100 hectares. The first macs were planted 8 years ago and I really couldn’t argue with Bruce about his decision to pull out his best cane fields to plant macs when he explained the disparity in income between the two crops: Macs can bring in up to 40 times what sugarcane does, in the same size area. I couldn’t help but ask the obvious: why any cane then?

Diversity. It’s a term I hear more and more and one that makes complete sense. Multiple income streams are always a good idea and one that Mike started practicing way back in Bergville days – mixed farming will always be the Zunckel norm. Besides, “Macs require a lot of finesse, diligence and chemicals”, says Bruce “It’s nice to balance that intensity with an easier crop like cane. The two also link nicely in terms of seasonality; if this was purely a sugar cane farm, the staff would be down to a few drivers right now, but, because of the macs, I am able to keep about 30 people employed year-round.”

I found this fascinating: Bruce plants cane between the mac trees when they are young. This provides windbreaks for the young trees and maximises land use. This cane is trashed and the organic matter spread under the trees. The cane itself is used for seed and the surplus goes to the mill.

I found this fascinating: Bruce plants cane between the mac trees when they are young. This provides windbreaks for the young trees and maximises land use. This cane is trashed and the organic matter spread under the trees. The cane itself is used for seed and the surplus goes to the mill.

Mike and Bruce now farm together in well-balanced, comfortable comradery. The mutual respect and admiration is clear. Bruce takes the lead but Mike is an indispensable source of knowledge and support.

CANE FARMING FOCUS

Starting right at the beginning; what factors go into the decision to plough out a field?

Variety and tonnage. Previously, age and tonnage were the factors that went into deciding what to take out but the Zunckels are trying to get rid of all the N27 & N39 currently, so variety comes before age at the moment. A few years back, these two varieties were Mike’s favourites. “And he planted them everywhere!” says an exasperated Bruce. Mike defends his decision, reminding Bruce that they were really great performers … for the first 3 or 4 ratoons … and then they ‘ran out of legs’ but, by then, about 50% of the farm was planted to them. You just never know exactly how a variety is going to perform over its lifespan. The Zunckels have also changed their average growing cycle since 2015 and that may also have contributed to the variety’s poor performance.

Another factor to consider is poor tonnage – at the moment, the same culprits are usually responsible on this farm, but low tonnage in any variety is always a factor to keep the radars focused on.

Generally, the 10% annual plough out rule is used at Havelock.

So, picking on the N27 and N39, you do the final harvest and then what?

Yes, the final crop of fields to be replamted is carried over into the new season so these are the first fields cut. We harvest and then allow the cane to ratoon and when it is big enough to respond to herbicide, Round Up is applied.

Regardless of soil analysis results, 2t/h (or more, if recommended by SASRI) of lime is then applied. This is something the Zunckels have done since Bergville days and they believe in its benefits. Once the lime is down, they deep rip and, if the soil is particularly compact, they will cross rip so that the lime moves through the layers and deep into the soil. If the SASRI recommendations suggest gypsum, they’ll add that to the lime. After ripping, the fields are harrowed.

Here, we can just see the soya starting to pop through a field that will lie fallow and recuperate until next year.

Fields are prepped. What’s next?

Since 2015, we have started incorporating a fallow period wherein we plant a cover crop. The cover crop in now is soya although we have tried a summer mix, sunhemp or black oats prior to this. The summer mix comprised sunflower, sunhemp and feed sorghum but they found it too difficult to get rid of the sorghum. “Possibly, we should have cut it sooner as it had gone to seed by the time we disked the crop in, but anyway, we are trying soya this year,” says Mike.

During this fallow period, they make sure that all cynodon is eradicated. If there was any RSD, that would also be eliminated in this fallow period as well.

The cover crop stays in for the required time and is then disked into the soil.

You have only been planting a cover crop since 2015 – what prompted the change?

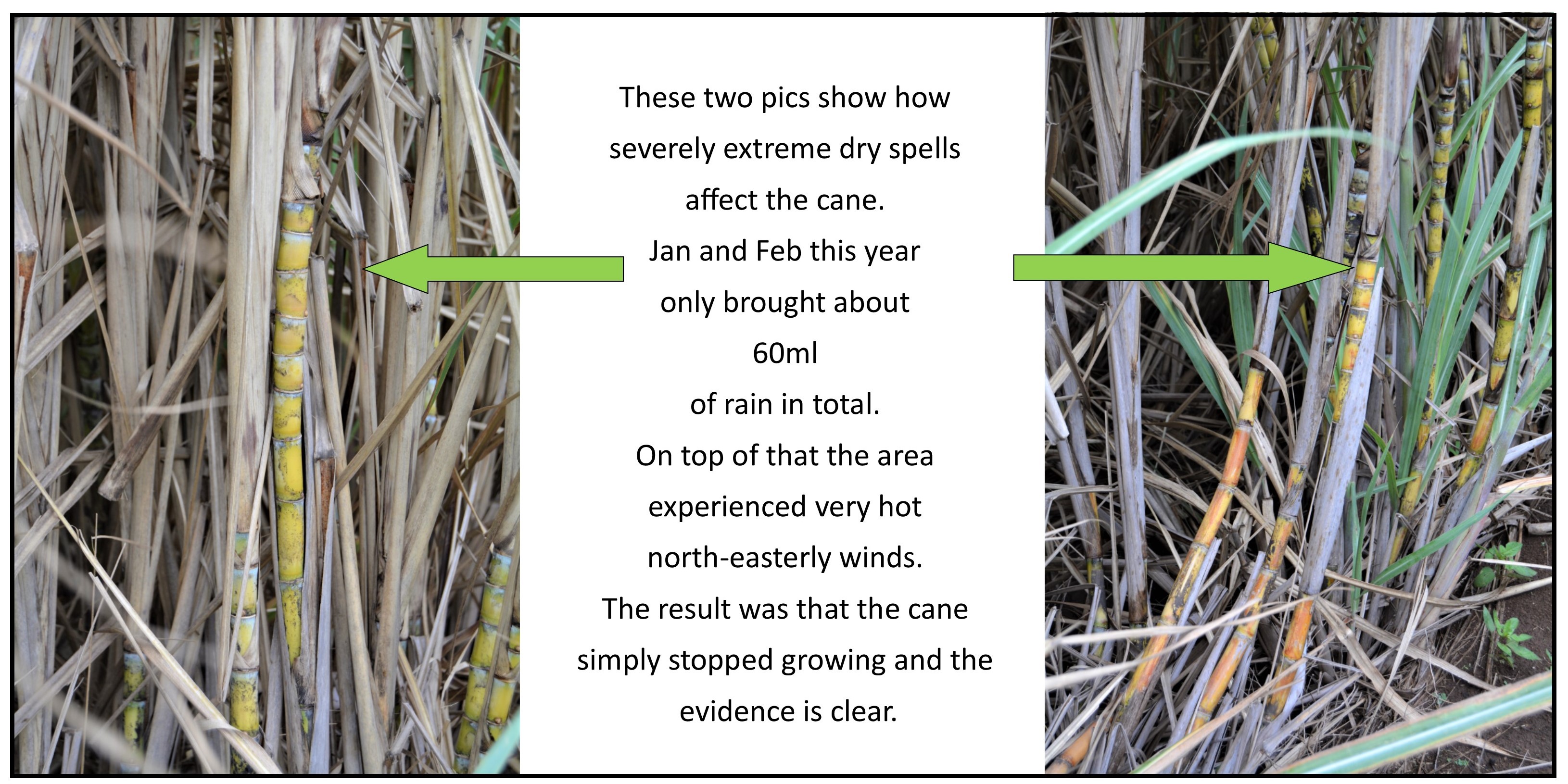

“The drought predominantly. Harvesting and prepping for a new crop carries expenses and, faced with dire drought conditions, we needed to assess affordability and timing of all activities.” Guy Ducasse, an economist who was employed at SACGA but has recently moved to one of the milling companies, sat with the Zunckels and crunched MANY numbers. The outcome was that it would be financially astute to carry the cane over rather than harvest. In reality, the bottom line looked better by about R300 000 because of this decision.

The spill over consequence was that all activities were pushed forward and, in order to get back into sync, they needed to leave the fields fallow before replanting. The benefits have become evident and a fallow period is now standard practice at Havelock.

Another factor that justifies a fallow period is the eradication of RSD; because the Zunckels allow a field that is to be ploughed out to germinate to the point where Round Up can kill it completely (so that they were sure it was RSD-free), they would sometimes end up in ‘planting season’ until late in December. A fallow period takes the pressure off and planting is now over before the end of November, after a year of lying fallow.

Okay, fallow period over – time to plant – what’s the process?

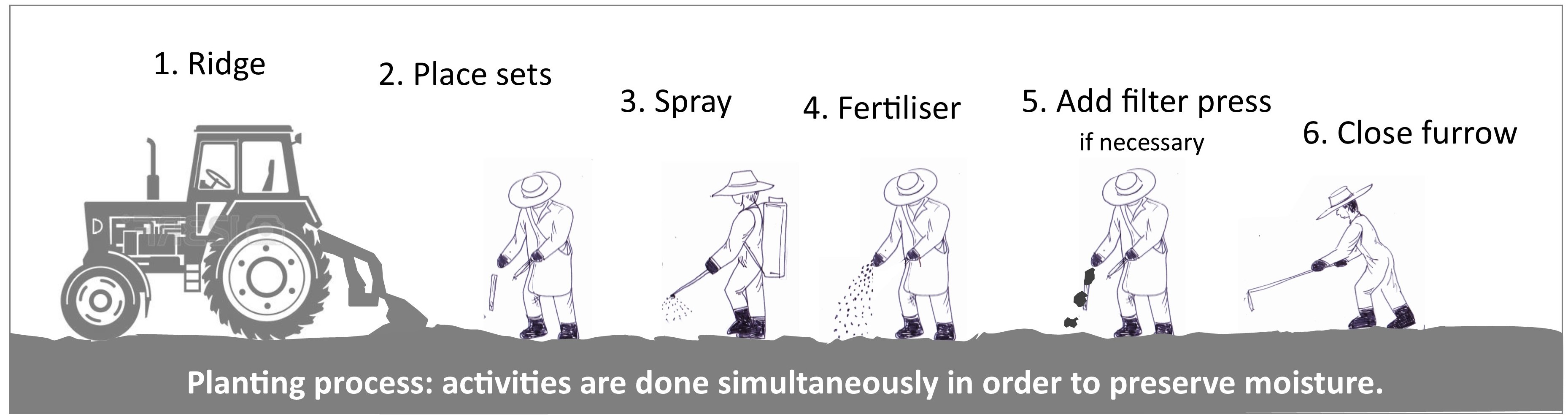

The cover crop is disked in. And then the interesting planting procession begins:

- Ridging: The tractor leads and cuts a furrow.

- Placing sets: Seed cane is placed in the furrow.

- Spraying: A mix of Bandit (for Thrips) and ProAct is sprayed onto the sets. ProAct is a product derived from harpin protein, a patented signalling molecule, and claims to assist germination, yield and plant health – it has been used by the Zunckels for the first time this year so we have no feedback yet but, it’s nice to know about the latest offerings … Other products Bruce is trying out is Root Stim or Myconate, which is a natural mycorrhizal stimulant that will trigger good enzymes around the roots and stimulate growth.

- Fertiliser application: Bruce uses whatever Kynoch’s recommendation calls for, usually a 2:3:4.

- Moisture preservation: Soil moisture content dictates the timing of this entire process. If at all possible, Mike and Bruce avoid planting into dry soil. If it’s winter and rain not likely then they use filter press on top of the sets, before closing the furrow, to compensate.

- Close up quickly: Then the furrow is closed, having been open for the shortest time possible and maximum moisture preservation achieved.

How do you decide what variety to plant?

For longer growing cycles, Bruce’s preferred varieties are N12 & N47 but they also have plenty of N41, N36, N39 and N27 . Lately, the new 50’s are also being used extensively, with N55, N58 and N52 being planted.

Any additional care before canopy is reached?

As soon as the cane starts to emerge, a long-term herbicide is applied. This year, Dynazone worked well on the wheaty type grasses and guinea fowl grass. A Merlin /Valpar mix was used for, amongst other weeds, barby grass. Once the cane has reached knee height, a top up of fertiliser is applied, as per Kynoch recommendations.

A light hand-weed to get rid of any old stools and remaining weeds the cane is left to grow.

Waterways are preserved and aliens removed. Mike has planted them up with indigenous species.

Waterways are preserved and aliens removed. Mike has planted them up with indigenous species.

Do you have to use pesticides at all?

Eldana is a real challenge in this area. So much so that the mill offers subsidies to spray against the pest. The farmers need to choose between receiving assistance with ripening or Eldana issues. The Zunckels have chosen to go with the Eldana programme and use their own Jacto applicator to apply the chemicals. They couldn’t be happier with this piece of equipment and happily report that it covered its purchase price in the first season.

The Eldana programme involves spraying carry over cane 4 times. The first two of these use Ampligo, starting in August when the first moth peak occurs. It is repeated about 2 months later, and 2 months after that Steward is sprayed which covers the crop until the new year. Coragen is then applied in February or March, in anticipation of the next moth peak and covers them for 6 weeks (Bruce says the official label says 8 weeks but he prefers to err on the side of caution).

Spraying carry over cane is not optional in this low-lying, wet environment; last year, one field missed 3 of its sprays and an expensive lesson was learnt.

Besides Eldana, Thrips and Aphids also need to be managed, but on a reactionary basis ie: they do not run a preventative programme for these pests but quite often need to respond when infestations are found. Again, the dreaded N27 & N39 varieties are usually the most susceptible and Bruce gives his Dad a wry, sarcastic smile of appreciation for planting so much of it. Mike shakes his head at the playful digs he frequently receives on these varieties.

Rust also requires a preventative spray and Bruce uses Amistar and Abacus to keep this issue under control.

Do you ripen?

Yes, but no longer as a rule. Bruce now uses the refractometer to make ripening decisions and realised that he did not need to ripen any of the carry over cane this year. He looks out of the window, at the beautiful rain falling today, and says that he will need to ripen the seasonal cane if this continues, up until the start of winter.

The Zunckels have always used Fusilade but are now moving over to Moddus because of RV results and flexibility. Darnall mill is over 100 years old and last year, break downs had dire consequences for the Zunckels who had applied Fusilade in anticipation of harvesting. The 8-week window expired and the cane started getting side shoots and lost RV before they could harvest. Depending on what services are available, Bruce contracts in either microlights or fixed wing aircraft to apply the ripener.

Time to harvest …

Bruce prefers a cold morning burn but, if wind and rain get in the way, he will revert to burning whenever feasible. They have recently moved from cut and windrow placement and Bell loading to a cut and stack method of harvesting for three reasons;

- Increased RV: RV levels increase when ash content is reduced. Ash (sand) in unavoidably incorporated when using mechanisation to lift the cane from the ground. Bruce found that as much as 4% of their load comprised ash and, besides affecting RV, this ash also causes mill challenges. Since changing methods, his ash levels have reduced to 1,5% (during last year’s wet season) and RV has increased by 1%. Bruce carefully considered the labour costs associated with the cut and stack method before making the change but is happy to report that the income from the higher RV covers the labour AND there are additional hidden benefits that Bruce feels are of even greater value, see point 2.

- Compaction: With minimal in-field traffic, the soil remains aerated and root health benefits, resulting in longer ratoon life. As replanting a field seems to get more expensive all the time, this is a huge benefit.

- Better base cutting: When the cutters realised that cutting LOW worked in their favour, ‘spunzi’s’ have disappeared. The base of the cane, being so rich in sucrose, adds to the higher RV% levels now being realised. Of course, the cutters have also realised that what applies to the bottom also applies to the top and the temptation to top-cut poorly is real. Fortunately, there is an excellent Induna who watches this with an eagle eye.

After stacking the bundles are taken to the loading zone on a 5t side loading trailer where they are weighed on a weigh bridge and then dumped so that the Bell can load into the transport trailers.

Another important harvesting practice is to prevent RSD from spreading – this is done by dipping all cane knives into Jeyes Fluid every morning and every field change.

What about Labour?

It was wonderful to hear that the Zunckel operation prays together every morning at 5am; all the staff gather at the workshops and enjoy a bible reading, short message and prayer in Zulu before receiving their tickets and instructions for the day. It only takes 5 minutes but enriches the solidarity and fosters a sense of unity when everyone bows to the same Lord and starts their work day together, under His will.

Bruce says they have a really fantastic work-force, many of whom have been with them ‘forever’. Mike lays much of the tribute at Bruce’s feet when he explains that Bruce is both strict and very fair at the same time, saying that his son is far better at managing staff than he ever was. Bruce says that his years of being an employee overseas taught him what it’s like to be on the other side of a working relationship; he learnt how he would like to be treated and remembers that when dealing with his staff here on the farm.

In season, there are about 100 employees, and out of season, this is cut back to around 30 of the best who help with the macs and litchis and general off-season chores.

These fertile valleys will soon be planted with macs. The Tugela river runs strongly in the background.

These fertile valleys will soon be planted with macs. The Tugela river runs strongly in the background.

How is administration handled here on Havelock?

This is an evolving department right now. Historically, it has been very pen-and-paper based, with one of their most trusted employee’s, Stanley, capturing all data the old-fashioned way. Stanley’s father worked for Cheryl’s father so he’s practically family! In anticipation of Stanley’s retirement, the Zunckels are taking the opportunity to modernise a little; Bruce’s wife has just started to get more involved and is using CanePro and Plan-A-Head to make the office a more productive and current environment. All accounting is handled by family accountants, Roberts and Chaplin, who Mike and Bruce meet with on a regular basis to plan finances and budgets.

How do you manage crime?

Bruce admits that security is one of his passions and one that is shared by many of his close neighbours. Together they are extremely vigilant about all activity in their domain. As a result, crime is low and swiftly dealt with.

Do you have any final pearls of wisdom that I can offer other aspiring cane farming champions?

- Planning is vital. Think very carefully about everything you do, especially in the planting phase which sets the foundation for that field’s yields for the next 10 years.

- Attention to detail. I hear so many top farmers advise this but have never really understood how it looks in practice but, with the Zunckels, there was clarity: things need to happen WHEN they should, HOW they should, in the right QUANTITIES they should, with the right level of QUALITY. Being purposeful in all that you do is achieved by going to that next level– the level of detail. I hope that all the future SugarBytes farmer interviewees are reading this and have a new sense of tolerance when I practice my “attention to detail” skills in understanding your greatness.

- Take advice from others.

Bruce stopped next to the dam to sample the guavas while we were having a discussion about the monkey issues and how they were dealt with. Somehow, our wires got crossed and I thought we were still talking monkeys but Bruce had moved on to guavas … he said “Mom stews them.” I stared at Bruce, completely unsure about how to respond to that. He stared at me because I was gaping at him in horror. It was an awkward moment until we both realised the misunderstanding, and then we laughed hard!

Bruce stopped next to the dam to sample the guavas while we were having a discussion about the monkey issues and how they were dealt with. Somehow, our wires got crossed and I thought we were still talking monkeys but Bruce had moved on to guavas … he said “Mom stews them.” I stared at Bruce, completely unsure about how to respond to that. He stared at me because I was gaping at him in horror. It was an awkward moment until we both realised the misunderstanding, and then we laughed hard!

I feel richer for having spent time with the Mike, Cheryl and Bruce Zunckel. You are all so gracious for having given me your time, sharing your knowledge, and I was spoilt to a wonderful warm lunch as well. I felt like I have been amongst pioneering, agricultural royalty and I hope that everyone reading this article has taken something from your experiences.

Thank you.