Canegrowers has the mandate to serve our industry’s growers – to help advance their sustainability. Sustainability and Diversity are bedfellows (as we’ve all found out ). In this light, Canegrowers’ Innovation Group is a committee that researches and assesses options that will ultimately make, or save, the grower money. I met with Richard Howes, who presently heads up this exciting committee, and he briefly introduced their three current focus areas: Biogas, Sugarcane Juice and Stevia.

Biogas will help all farmers save costs and secure a more consistent and controllable energy source. Sugarcane Juice, with the right market, could create an alternate demand source for sugarcane. And Stevia fulfils the Diversification option. It’s a crop that has ticked all the boxes so far and is therefore being rigorously assessed for release to the market, specifically sugarcane farmers, via Canegrowers’ commercial arm: Womoba. It’s ‘early days’ yet but this article will be an introduction for everyone scouting to supplement their farming operation.

What is Stevia?

Stevia is a shrub with sweet leaves. It is native to South America. The sweetness can be extracted and processed to produce a sweet powder, 300 times sweeter than sugar. It has zero glycaemic index and zero calories and is therefore a perfect non-nutritive sweetener. The fact that it is plant-based makes it more desirable than most of the options in this market.

Stevia plantation

Stevia plantation

Stevia is an unnervingly exciting crop that is very new in SA. (I’m frantically trying to assess whether there are any wealthy family members willing to invest in a farm for me )

All available Stevia powder in the country currently has been imported. But there is no reason why it cannot be grown, extracted, marketed and become a booming industry here.

Richard has the answers to your most pressing questions:

Why hasn’t it been grown here already?

Up until now the South African industry has been stunted by a few obstacles:

- Non-nutritive sweeteners often have an unpleasant after-taste and “mouth-feel”. Anyone who’s tried it can attest to this. We haven’t managed to produce an acceptable Stevia product locally.

- Processing and formulating the product into a marketable form.

- Non-availability of modern cultivars of Stevia; ones that yield economically feasible biomass and steviol glycosides.

- Lack of widespread knowledge about modern farming technology, related to Stevia, that will ensure a predictable return.

These challenges have been addresses since Wostevia established a partnership with Shantanu Chakraborty of Stevia Technology in India. This chemist and agriculturalist is one of the best in the world when it comes to this crop. He has been out to SA to assess our local conditions and strengthen the ties with our fledgling industry. He currently lives in India and continues to work on refining the farming, extraction and formulation of Stevia. He loves our country and may even consider relocating to our sunny shores …

Top left, moving clockwise: Shantanu in the Guatemalan laboratory, Indonesian farm, Indian trial field, Guatemalan farm, Indian farm, Shantanu with Dr Thomas Funke and Richard Howes whilst visiting South Africa.

Top left, moving clockwise: Shantanu in the Guatemalan laboratory, Indonesian farm, Indian trial field, Guatemalan farm, Indian farm, Shantanu with Dr Thomas Funke and Richard Howes whilst visiting South Africa.

On the farming side, Shantanu is working on genetic improvement and the development of new cultivars that, among MANY other things, will have better pest resistance, a higher content of the desired glycosides, a higher endurance to environmental stresses, lower field mortality rate, efficient carbon sequestration and high water use efficiency. On the extraction side he is working on ways to minimise costs and maximise efficiencies. And, when it comes to formulation, he invests in getting the right formulation that best simulates the taste and feel of sugar, at optimal efficiencies and quality levels.

Wostevia is a company that has been established by Womoba, Canegrowers’ commercial arm, to support the industry and take it to the next level.

How easy is it to grow?

Shantanu explains that there are three pillars to successfully farming Stevia:

- Selecting the correct variety

- Hosting in suitable soil and agro-climate

- Providing proper crop management practices

VARIETY – We need a variety that is not only suitable to our climate but also delivers the best taste, content and quality when processed. Richard has the plants available and they slip easily (more on this in ‘Planting’, below).

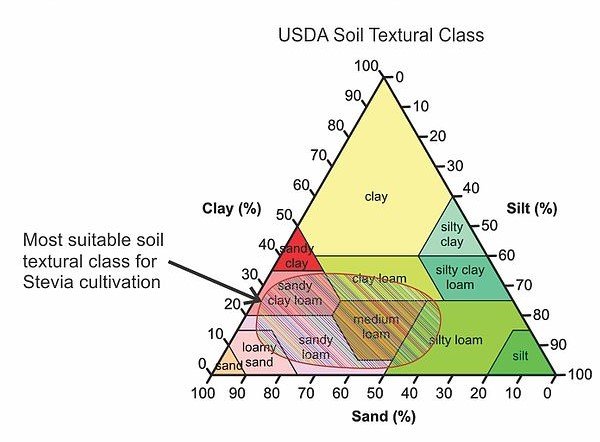

SOILS & CLIMATE – Stevia grows well on most soils, but prefers a sandy loam or loam, high in organic matter. Its native soils are on the acid side, but stevia tolerates a wide range of soil pH, and pH 6.0 to 7.5 is the optimum condition. Stevia likes consistently moist soil, but not waterlogged. Standing water can cause plant rot. Except in the case of very sandy soils, raised growing beds provide Ideal conditions. Stevia does not grow well in saline soils.

The soil texture class is determined by the percent of sand, silt and clay in the soil. The USDA classifies soil types according to a soil texture triangle chart which gives names to various combinations of clay, sand, and silt. This chart indicates the range of the textural classes suitable for Stevia cultivation.

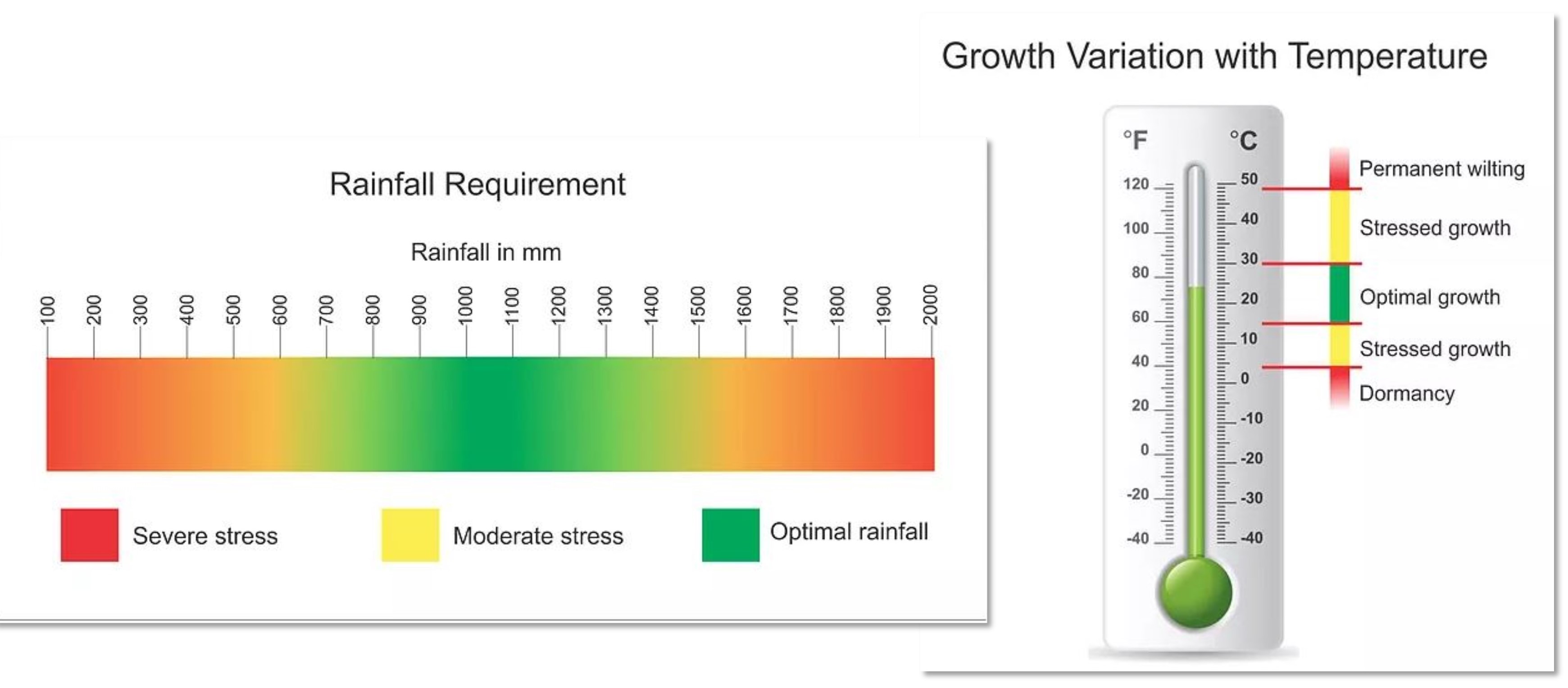

Stevia grows as a wild plant in semi-humid, sub-tropical climates where temperatures typically range between -6°c to 43°c. It is a long day plant and requires 12-16 hours of sunlight per day and is sensitive to excessive heat and low temperature. Long spells of higher temperature may inflict heat stress to the plants and they may wilt. The plant can withstand mild frost but heavy frost may adversely affect the roots. The optimal temperature for growing Stevia is between 15°C to 30°C. Long cold spells are also undesirable as it can affect the growth rate and can make the plants dormant. The day temperatures should not exceed 48°C and the night temperatures should not fall below 4°C.

Annual average rainfall of 1100 mm per year has been found optimum for its good growth. This means we will need to irrigate in SA to get the best results – the crop is harvested 3 to 4 times annually so our dry months won’t yield a good crop without irrigation.

The flowering is directly linked to the duration of the photoperiod and accelerates during short days. Flowering always decreases steviol glycoside and biomass yield.

BEST CROP MANAGEMENT PRACTICES – Stevia is a fairly robust plant and our farmers are generally a diligent and astute bunch. From what I’ve learnt about the crop, we are well equipped to tick this box.

Who is the market?

Traditionally, Stevia has been produced in liquid, granular, tablet and cube form. It can be packed in sachets, bottles, retail packaging or industrial size packs. Users are home consumers, beverage manufacturers, bakers, dairy product manufacturers, confectioners, breakfast cereal manufacturers, fruit processors and preservers, manufacturers of sauces and condiments and the pharmaceutical companies. Wostevia will set up an online marketing arm to supply end-users and establish direct links with industrial users.

As the health focus continues to gain momentum worldwide (the same drive that is believed to be behind the growing popularity of nuts) so will the demand for non-nutritive sweeteners and natural, plant-based options will be preferable and demand a premium price.

What is the size of the market?

The conventional sugar market growing at about 2% per annum (although shrinking in Westernised, 1st world countries, it is growing in 3rd world markets). Non-nutritive sweeteners are growing at around 3,5% and Stevia is growing at over 8% as is the most sought after source because it is natural and doesn’t have any of the health concerns that the synthetic products have – Aspartame and Sucralose have particularly poor reputations.

As mentioned, South Africa is currently importing all of the Stevia used here so the potential to supply a local market is at its max.

How much money can be made?

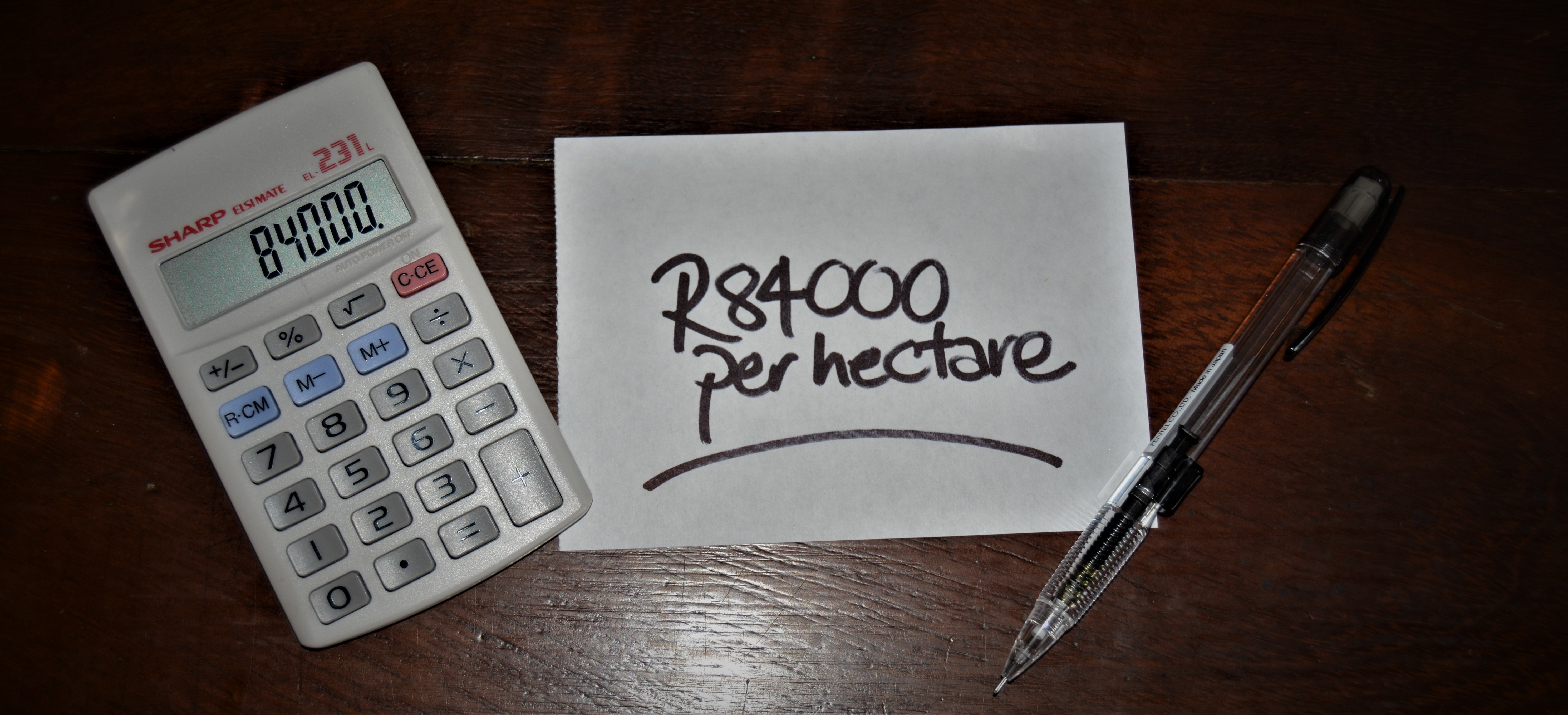

Richard has crunched the numbers based on a 10-hectare piece of land …

… an annual gross profit of R84 000 per hectare is the estimated return for a Stevia crop (dry leaves). Gross profit, in this case, is the income less direct costs. Overheads have not been accounted for.

So, if you just sell the dry leaves, your annual profit, will be R840 000. But … the real money-making opportunity lies in the processing of the leaves yourself. This is something that should be carefully considered as transporting bulky, dry leaves can be an expensive exercise and Stevia powder is currently fetching $USD 55 000/tonne. At today’s exchange rate that is just short of R800 000.

A hectare of stevia should produce about 6,5 tonnes of dry leaves annually. So, if we again work on a conservative 10-hectare plot, your annual crop will be 65 tonnes. The powder from 1 tonne of leaves is about 100kgs. So, the 10 hectares will result in around 6,5 tonnes of powder. I am sure you are all way ahead of me with the calculator and you don’t need to redo the calculation because that is R5,2 million you are seeing on your screen.

The processing plant that Shantanu has developed is small and affordable, given the returns. The cost is about $USD 35 000 (approx. R510 000) and can be shipped in a 20 ft container from India. The electricity consumption is relatively low, with the processing plant requiring only about 8 to 10kW. It is also fully automated and basically just requires you to put dry leaves in one end, press a few buttons and stevia powder comes out the other end. Obviously, I am exaggerating the simplicity but it is not complicated and even techno-phobes like myself could “drive” one.

Where do I get the plants?

Richard (through Wostevia) is supplying the original plants. They are the variety developed by Shantanu and are an essential element in a successful outcome. Any growers receiving plants will be required to sign a legal document defining the agreement that will be in place when receiving these plants. You will be given 2 trays of 30 plants. These can be slipped every 14 days.

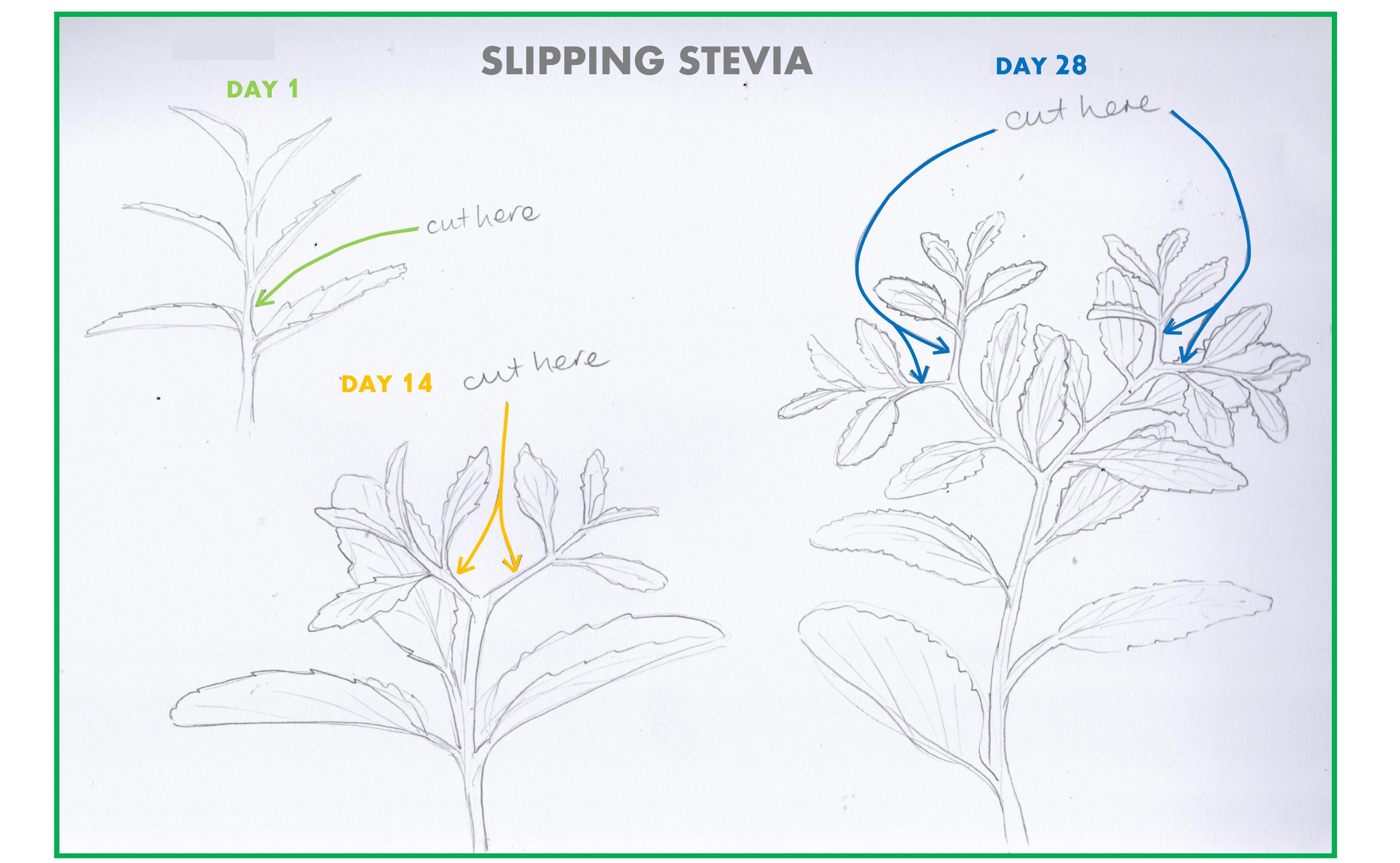

When you cut a stem, two shoots grow back, doubling your stock for the next clippings. And, after just 14 days of germinating its own roots the “new” plant will also be ready to slip.

When you cut a stem, two shoots grow back, doubling your stock for the next clippings. And, after just 14 days of germinating its own roots the “new” plant will also be ready to slip.

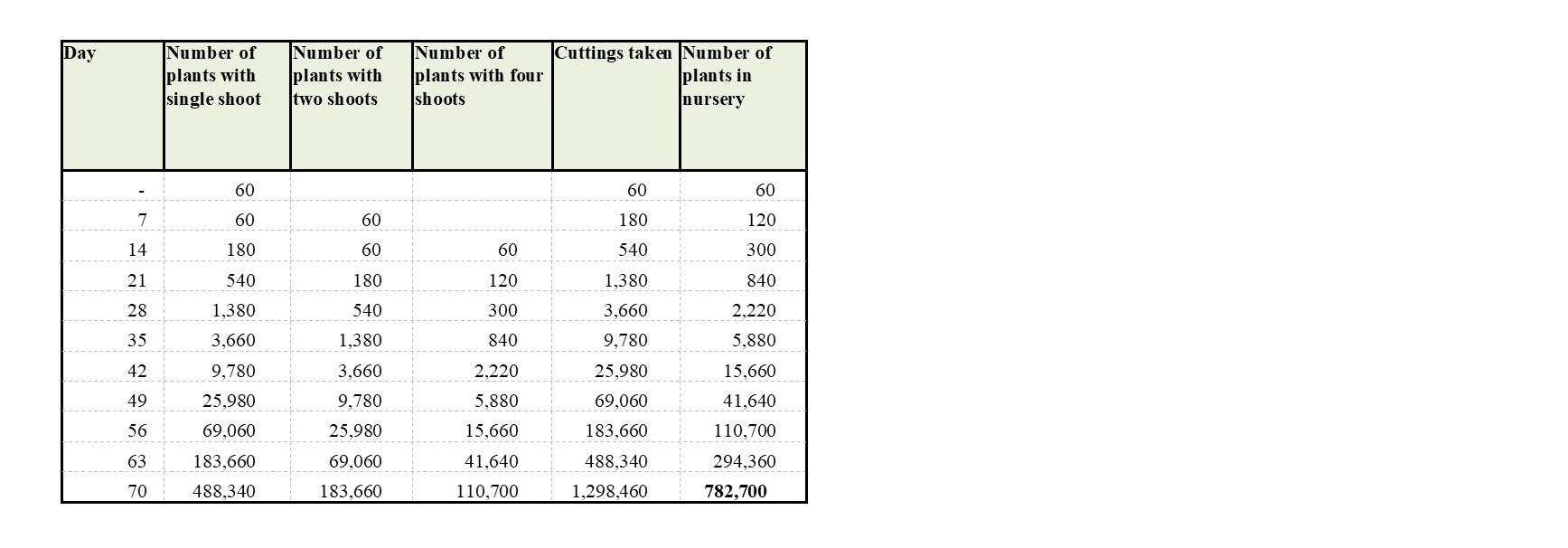

If you start off with 60 plants, and slip them every 14 days, within 70 days, you can have bulked your nursery up to 782700 plants. (table below)

Recommended planting intensity, in-field, is 150 000 per hectare. A 10-hectare plot will therefore require 1,5 million plants. Using the projections above, you’ll be able to achieve that in less than 5 months.

How will this industry be managed?

We all know that Canegrowers’ faces the challenge of continuing to provide top-shelf service with a bottom-shelf budget and have therefore had to supplement their income by stepping into the world of commerce. They have done this by establishing Womoba (translated: ‘from sugarcane’). This business will then parent any other ventures that show promise. One of these is Wostevia.

Wostevia will operate in a very similar structure to Mayo Macs or ZAH (Zululand Agricultural Holdings) and a number of other investor/supplier-based operations wherein the people that invest are integrally linked to the company’s business. As a Stevia farmer, you can both invest in and supply this company who will then see to the research, marketing, support and development of the entire supply chain.

Some of the services to be offered by Wostevia, come the beginning of 2020:

- Stock supply.

- Extension services to guide you through the farming of Stevia.

- Marketing

- Creating a local Retail market.

- Creating a local industrial customer base. Wostevia will be importing Stevia powder to awaken the two markets above. When local supply gets into production, the imports will be replaced with locally grown product.

- Buyer

- of dry leaves.

- of processed Stevia powder.

- Formulation: a lot of technical expertise goes into the formulation of the final product, depending on the market it is supplying. In a household use, only 1,5% of a sachet of Stevia powder is actually Stevia, anymore would make it intolerably sweet. The balance is bulking agent.

- Packaging

As a supplier of the plant stock, Wostevia is confident that they will be able to manage supply and demand optimally. As mentioned early on, it is very early days and the landscape will inevitably evolve as the hills and valleys of pioneering are traversed. There are no guarantees – your appetite for risk will decide whether you’re ready to get into the details of farming this crop yourself …

What are the details of growing this crop? (Planting, harvesting, pest management, weed control etc)

Planting

Once your nursery has delivered all the stock you need, it’s time to get them into the field. The plants will be ready for planting out when they have been in a seedling tray for about 4 weeks and are at least 15cm tall.

Germination of new plants must be done in a seedling tray. Rooting hormone is not required. Richard is having 100% successful germination with his stock (pictured above). He fills trays with soil, places the tray in a bath, allowing the soil to soak up the water by capillary action. He then sticks a slip, with 3 or 4 leaves on it, into the soil. He covers the tray with a lid, leaves it in a warm, shaded area, sprays the leaves with plain water twice a day for a week and continues the slipping process every 14 days.

Germination of new plants must be done in a seedling tray. Rooting hormone is not required. Richard is having 100% successful germination with his stock (pictured above). He fills trays with soil, places the tray in a bath, allowing the soil to soak up the water by capillary action. He then sticks a slip, with 3 or 4 leaves on it, into the soil. He covers the tray with a lid, leaves it in a warm, shaded area, sprays the leaves with plain water twice a day for a week and continues the slipping process every 14 days.

Soil preparation is standard – it is recommended that a green crop is ploughed into the soil before starting. Acidity levels should also be adjusted with lime and or gypsum at this stage. You can then refine a good tilth in the soil and decide whether you’d like to create raised beds or not.

Irrigation is recommended, in fact Richard says it’s essential. If you use drip irrigation then mulching sheets are going to save on herbicides and can have an impact on pest management as well. Silver mulching blankets reflect light onto the underside of the leaf which not only increases photosynthesis but also disturbs any bugs that rest under the leaves.

Spacing plants at 20cm x 20cm intervals will allow you to get 150 000 plants into a hectare, with sufficient light penetration to maximise growth.

These plants are small enough that it is an option to consider using the corridors of a young, pre-production mac orchard. The mac irrigation (if microjets) could be adjusted to extend into the inter-rows and produce a very valuable cash crop off dormant land.

Some images taken from Shantanu’s website, of his planting in Guatemala.

Some images taken from Shantanu’s website, of his planting in Guatemala.

Crop Care – Nutrition

Shantanu advises that, “Stevia needs balanced nutrition for proper growth and glycoside production. Although Stevia was originally portrayed as a crop with little external nutritional support requirement, it has since been discovered that it responds very well to fertilizer application. The nutritional management program for Stevia depends on local soils and the prevailing agroclimate, the method of farming, variety and target yield. The fertilizer requirement for a specific farm cannot be guessed and there is no universal fertilizer recommendation.”

He goes on to explain what one tonne of dry leaf Stevia typically extracts 14 kgs nitrogen, 3 kgs phosphorus, 24 kgs potassium from the soil, so a nutritional plan that aims to replenish that would be a start. Shantanu recommends that this be split judiciously, with fertigation being the best option.

Stevia’s first choice of micronutrients are: Iron, Manganese, Zinc, Copper, Boron and Molybdenum, followed by Calcium, Magnesium, Sulphur and Chlorine.

Crop Care – Pests and Diseases

Given that there have not been any commercially successful crops of Stevia grown over a long period of time in South Africa, it is rather difficult to imagine what the challenges will be but, it is Africa, where everything wants to eat, maim or destroy so I have no doubt we will encounter attacks but we are also well equipped to deal with whatever the challenges are. Interestingly, Shantanu says that cattle never graze on stevia – their farm in Guatemala was frequently visited by cattle and, although they trampled the stevia, they never ate it. In India there have been sporadic reports of monkeys tasting stevia leaves but there are no reports of widespread damage. He went on to say that the accumulation of steviol glycosides in the leaves, which are unpalatable to herbivorous animals, is a survival strategy of the plant. Great news for anyone pulling their hair out over monkey, hog and buck damage.

Harvesting

Harvesting happens every 3 to 4 months (ie: 3 to 4 times per year). The option of hand-cutting is viable with smaller plantations and recommended in the early harvests because of height variations in the crop and the fact that young root systems may not be able to withstand the rigours of equipment.

If preferred, there are a number of mechanised options, the most popular being a sickle-bar mower, as seen below:

Other harvesting machines have rubber wheels that windrow the leaves once they have been separated from the plant. These leaves can be left in the field to dry or collected and hung undercover. A harvester can be imported from India, China, Europe or the USA. Of course, a standard brushcutter could also be used.

And once it’s been harvested, what then?

The post-harvest processing of Stevia involves three tasks:

- The leaves need to be dried.

- The stems need to be separated from the leaves.

- The leaves need to be baled.

Drying:

After the leaves are harvested, they are to be dried as quickly as possible to avoid the chance of browning and loss of steviol glycoside content. Up to half of the initial glycoside content can be lost within three days if drying is delayed. The initial moisture content of fresh leaves is approximately 80% and they are to be dried to a final moisture level of 10% for long term preservation. So the total loss of weight in the drying process is 78%. Higher residual moisture percentage in the leaves during storage results not only in deterioration of the glycoside content but also mould growth and decomposition – making the leaves unusable for glycoside extraction.

There are numerous options to dry the leaves, ranging from the rudimentary method of leaving them in the sun, to placing them under-cover on drying tables/racks, to drying tunnels and then there is sophisticated, specialised drying equipment – your specific circumstances will determine which is the best way to go.

The stems of Stevia plants contain very little steviol glycosides, so their presence reduces the overall glycoside content of your harvest. Moreover, stems elute a lot of tannin and waxy material during extraction, which interferes with the purification of glycosides. It is therefore important that the stems are removed. For very small farms, it can be done manually, but mechanical options include the simple mini defoliator – used on fresh cuttings, or a winnowing separator – used when the leaves have dried.

Dry leaves are extremely bulky, impacting storage and transportation of the product. Baling should perhaps be considered to minimise these costs.

Drying, defoliating and baling are important post-harvest tasks.

Drying, defoliating and baling are important post-harvest tasks.

At this point, Wostevia will take the dry leaves from you if it is as far as you want to go but, as mentioned, there is the option of processing the leaves and realising even greater returns from your crop. The processing equipment is the intellectual property of Shantanu. His first qualification was as a chemist so, when he realised that the existing technology, using resins to extract the glycosides, was not suitable for smaller quantities, he went about formulating a new extraction method – the same process he now uses to produce his world-class Stevia in India. This equipment can be manufactured locally, with Shantanu providing all the technical support required. Richard’s budgeted cost for this equipment is R500 000 – R600 000.

Left: Shantanu standing in front of his Formulation Unit. Right: The Extraction plant in India.

Left: Shantanu standing in front of his Formulation Unit. Right: The Extraction plant in India.

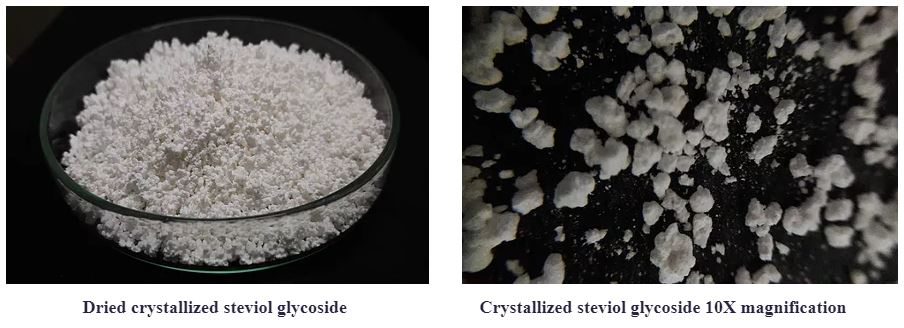

The dried leaves are first leeched in hot water, like tea, in trays. The liquid is collected and clarified through a process called electro-coagulation and filtration. The clarified liquid goes into a column, together with an alcohol-based solvent. The ‘tea’, being heavier than the solvent and having entered the column at the top, passes through the lighter solvent. During this ‘passing’, the solvent removes the steviol glycosides from the ‘tea’. After being carbon filtered and evaporated only the white steviol powder – your end product – remains! And all you had to do was put dry leaves in the front end and push a few buttons.

What are the timelines to get involved?

Richard is working towards getting processing equipment and having markets established in time for the start of 2020. Right now, he feels like Stevia is running faster than its feet can carry it and he is having to keep up and help it stay on track. Very exciting and very overwhelming.

In the meantime, interested farmers are welcome to contact him with a view to assessing your personal feasibility with this crop. Contact details at the end of the article.

There certainly isn’t a shortage of retail options in the market. Blind taste tests, conducted by Richard’s team, gave him the confidence that they have partnered with the right scientist in Shantanu as his product – iStevia, top left – came out tops!

There certainly isn’t a shortage of retail options in the market. Blind taste tests, conducted by Richard’s team, gave him the confidence that they have partnered with the right scientist in Shantanu as his product – iStevia, top left – came out tops!

In Conclusion

Our world is in a state of disruption. We see evidence of that in political instability, social conflict, massive technological bounds, revolutionary thinking in terms of health, nutrition, education … just about everything.

Whilst the initial reaction to that might be negative, we have the option of seeing the positive opportunities in it. Disruption destabilises; it shakes people from their perches and from under their rocks and it presents new breaks. You can choose to take these or you can choose to stagnate and risk being swallowed up into one of the canyons created by the seismic shifts. The sugar industry has been disrupted by a number of factors in recent years. That has put us at a crossroads of opportunity; let’s not resist and desist. Let’s rather shout “Bring it on!” and get out there to see where the fertile ground has become available. It is in this spirit that all our articles are written, but none more so than this one.

Contact Richard and see whether this is an avenue you should be exploring …

richard.howes@sacanegrowers.co.za Phone: 082 657 5553

Credit to the research resources I plundered: Doornextfarms.com, Fairsharinternational.com, Stevia.com, Wikipedia.com but a particularly grateful thanks to Shantanu, whose website: www.steviashantanu.com, I used extensively, and of course, Richard Howes, who is now our local Stevia-guru. I hope your hard work is paid off with the interest of ALL our farmers.